PremiumVision™

Prefilled Syringe Components, Vial Components

Pharma

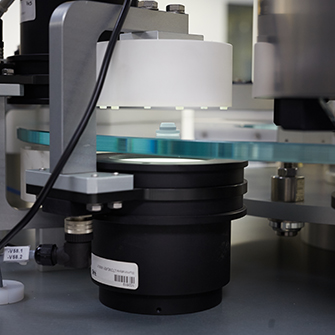

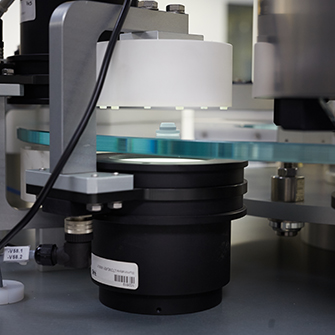

PremiumVision™ is a guaranteed quality commitment using our in-line, automated vision inspection system designed to further validate against critical defects after PremiumFill®. Aptar Pharma’s PremiumVision™ can be added to PremiumFill® to further enhance the level of quality and meet the defect detection level required for your injectable components needs, to further reduce risks.

Download Aptar Pharma Overview Brochure

Further Enhancing the Quality Level of Your Injectable Components

The highest customized levels of quality to meet increasing requirements

Because we understand that guaranteed quality is essential to our customers, we offer PremiumVision™, an automated visual inspection system that delivers our highest level of quality specification. PremiumVision™ is based on a project development approach in order to issue adapted specifications in line with your specific quality requirements.

State-of-the-art production processes further reduce risks

PremiumVision™ is a state-of-the-art automated vision manufacturing process that is able to detect component defects at a level not visible to the human eye.

PremiumVision™ can be combined with our PremiumFill® process to give you the highest level of quality for your Ready-to-Use (RTU) or Ready-to-Sterilize (RTS) stoppers and plungers. PremiumFill® is conducted within cleanroom conditions: the molding, trimming, and washing are conducted in an ISO 7 environment, and the finishing is conducted in an ISO 6 environment, providing further quality assurances to customers. By automating our processes and reducing human contact where possible, we further mitigate against the risk of errors, therefore improving the quality and integrity of the end product.

Customized development based on your project needs

Customized development is required for components that will be inspected using PremiumVision™. Customizable specifications include shape, color, formulation and quantity. We tailor the level of defect detection to your needs and adjust our solution according to your specific requirements. Our team will work with you to implement our formalized process to set- up and deliver our customized solution for you.

Premium quality offering to accelerate and derisk your drug development

PremiumVision™ is part of the Premium offering from Aptar Pharma, a holistic approach, from risk prevention to visual inspection, answering your specific needs and, ultimately, reducing risks and providing higher quality outcomes for your drug development projects.

PremiumVision™ Advantages

- Higher Defect Detection

- Cleaner End-Product

- Further Reduces Risks

- Customized for Your Project

PremiumVision™ provides a higher level of defect detection

Automated visual inspection to further validate against critical closure defects for stoppers and plungers.

PremiumVision™ detects visible particulates better than the human eye

PremiumVision™ uses a state-of-the-art automated vision system that is able to inspect each component’s surface and detect defects at a level not visible to the human eye.

PremiumVision™ further reduces risk when used with PremiumFill®

PremiumVision™ can be combined with our PremiumFill® process to give you an enhanced level of quality.

PremiumVision™ offers a tailored approach based on your needs

PremiumVision™ uses automated visual inspection based on a project development approach in order to issue a customized specification in line with your specific quality requirements.

See How PremiumVision™ Can Deliver Enhanced Quality

Contact an Aptar Pharma expert and see how PremiumVision™ automated vision inspection can deliver enhanced quality assurance for your projects.

We Offer World-Leading Support Services for You at Every Stage of Your Product Development

Start a Project With Us

We Thrive on Transforming Ideas into Opportunities – Let Yours be Next.

Request More Information

Requesting information on PremiumVision™.

How Can We Help?